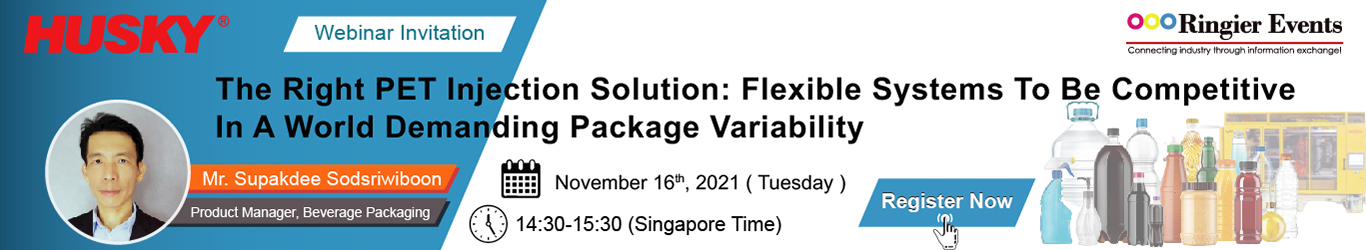

Webinar Introduction: The right PET injection solution - Flexible system to be competitive in a world demanding package variability

The packaging industry is seeing a huge trend toward more SKUs, shorter production runs, and more frequent design changeovers. To succeed in today’s evolving market, producers must ensure they are selecting the right systems that will provide the flexibility and adaptability to transform these market challenges into opportunities.

Who should attend ?

Brand owners

Food & Beverage producer

Preform converters

You will learn during this webinar :

How consumer preferences, SKU proliferation, sustainability, and COVID-19 are shaping today's market

How to select the right system can help you take advantage of evolving market challenges and turn them into opportunities

The latest advancements in system, tooling, auxillaries and service and how these work together to provide a complete, intergrated solution

Register now

Husky injection molding systems are leading the industry to maximize productivity, minimize part variability and reduce maintenance to enable the lowest total cost to produce.

Husky’s NexPETTM system is flexible, future-ready, and well-suited to beverage applications. With a large mold vertical pitch distance of 60 mm, it is ideal for sports drinks, juices, edible oils and ready-to-drink teas, and provides extra room to accommodate thread diameters as high as 40 mm. Plus, the NexPET mold features specially engineered hot runners that enable mold changeovers up to 25% faster—perfect for frequent, shorter runs and multiple preform SKUs

About HUSKY

Husky Injection Molding Systems is a leading industrial technology supplier to the plastics processing community. The company designs, manufactures and integrates the industry’s most comprehensive range of injection molding equipment, including machines, molds, hot runners, auxiliaries and integrated systems. Its value‐added services include preform development, part design, factory planning, customer training, systems integration and complete asset management.

Customers use Husky equipment and services to produce a wide range of products for the beverage packaging, closures, medical, thin-wall packaging, automotive and consumer electronics markets. With more than 40 service and sales offices and employing approximately 4,200 people worldwide, Husky supports customers in over 100 countries. Its main manufacturing facilities are located in Canada, the United States, Luxembourg, Switzerland, China, India and the Czech Republic.

Webinar inquiry, please contact :

Matt Wang / Ringier Trade Media Ltd.

Tel : +886-4-23297318

Email : mattwang@ringier.com.hk

REVIEW

Copyright © Ringier Trade.com. Copyright © Ringier Trade Media Ltd. © 2025.